PROJECT

井上製麺

そうめんメーカーのリブランディングや商品開発。老舗の歴史を読み解き、機械式製麺の元祖を日本初のゼロカーボン製麺企業に導く。

WHY

地域を持続可能にしてきた

信仰の衰退。

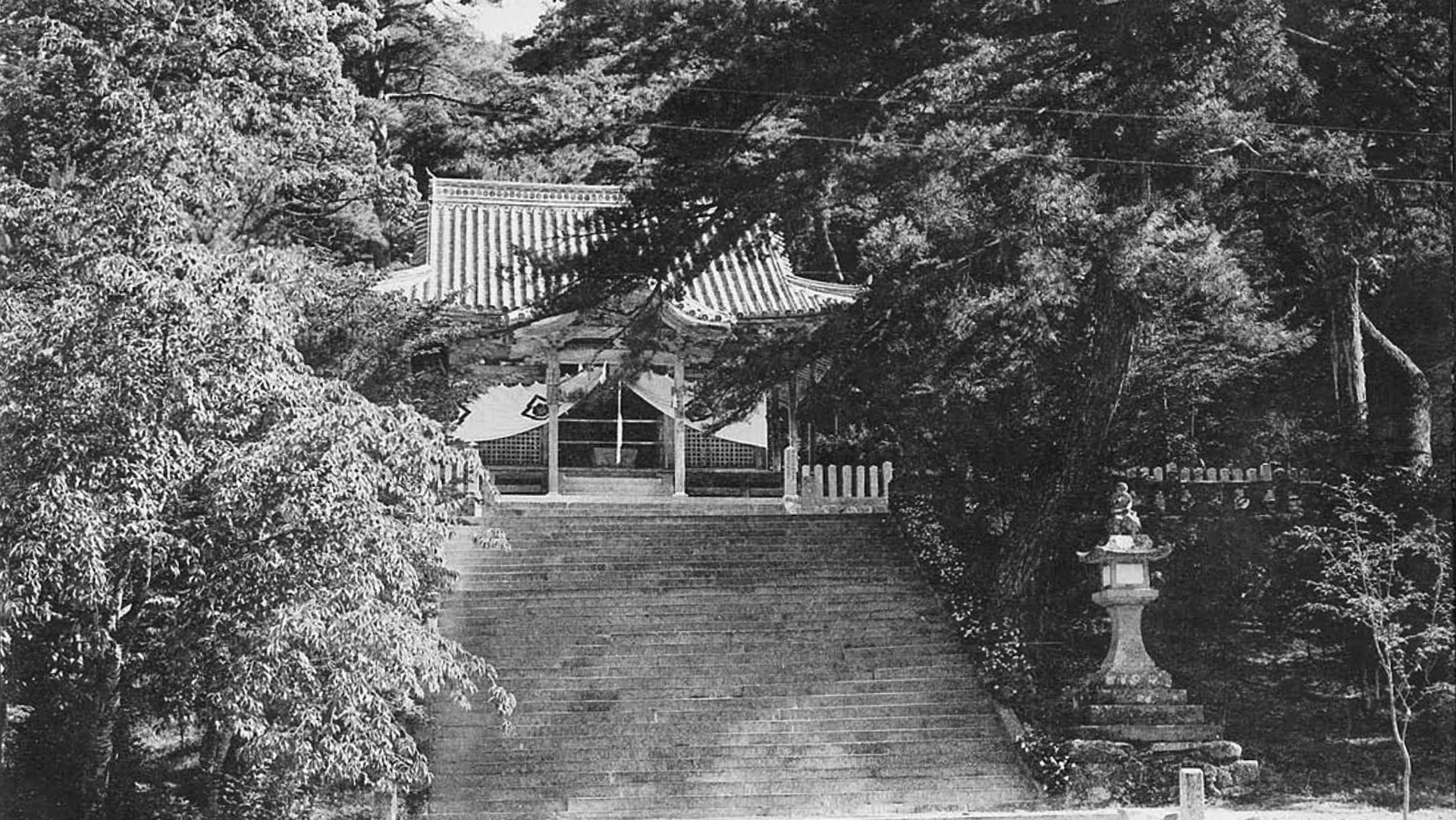

古来より、日本の地域産業やコミュニティ、そして自然信仰のシンボルは神社でした。現在の日本の地域の多くは、人材不足や高齢化、後継者難、地場産業の低迷など、さまざまな問題を抱え衰退の一途をたどっています。さらに近年では、人間社会による環境への多大な負荷によって、地場企業が頼りにしてきた水や食糧、自然環境など地域の天然資源が危機にさらされています。今こそ地域が一丸となってこうした課題に向き合う時であり、その時にも地域の神社は欠かせない存在でしょう。

しかしながら現在、全国の神社の半数は年間収入が300万円未満という厳しい状況にあり、地域文化の象徴である神社そのものの存続が危ぶまれています。生態系のバランスを維持し、原風景や文化を守りながら、産業やコミュニティを支えてきた地域の信仰を守ることもまた大きな課題なのです。

2016年神社一年間の収入

HOW

地球と地域と氏神様

のための素麺づくり。

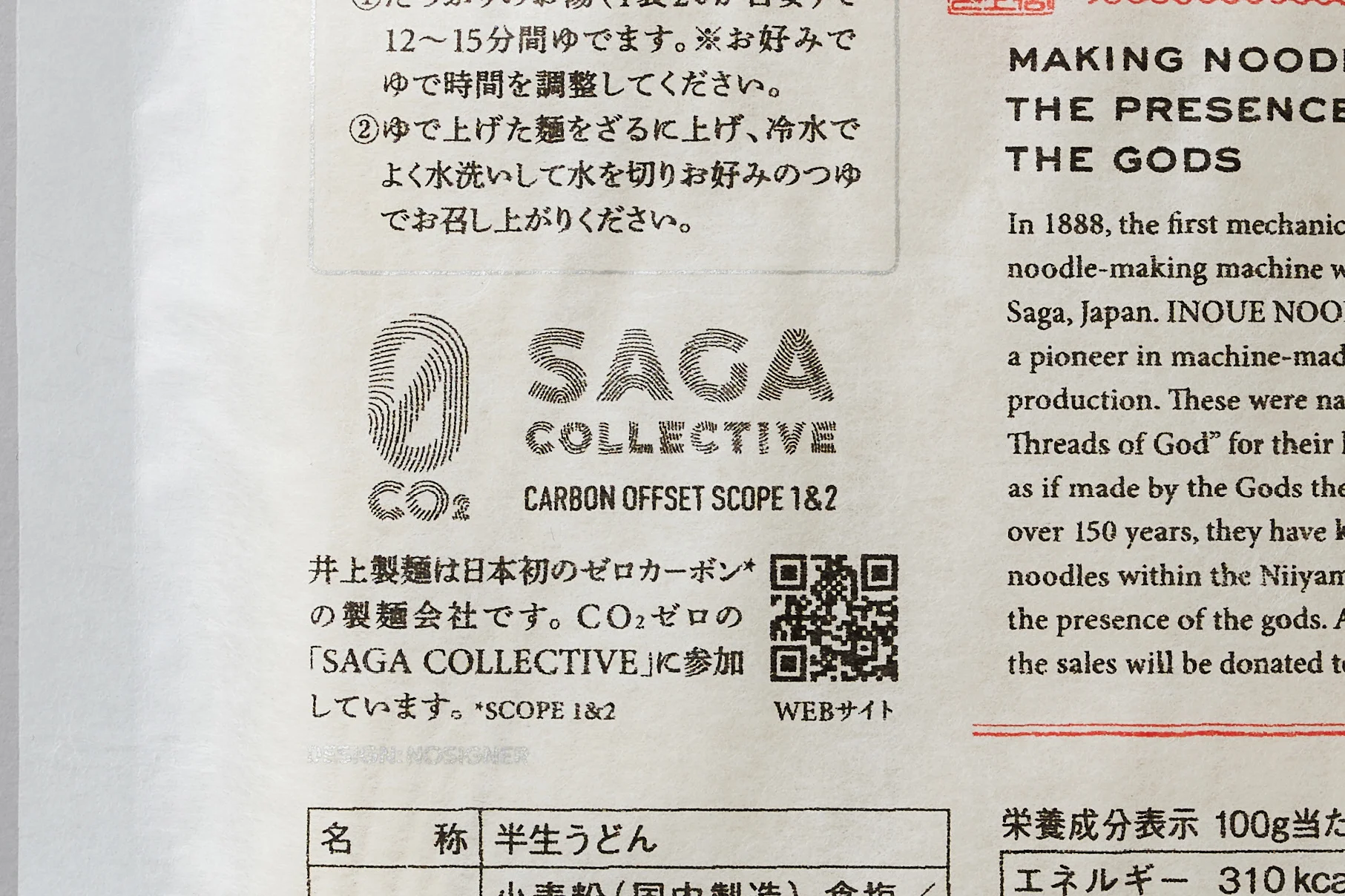

井上製麺は、1873年に佐賀の地で創業して以来、約150年にわたって麺づくりを続けてきた「神埼そうめん」の老舗です。佐賀の地場産業を牽引する中小企業11社による組合「SAGA COLLECTIVE」を、日本初の「全商品脱炭素済みの地域ブランド組合」とする取り組みを推進した際、私たちは井上製麺の二酸化炭素排出量の測定や削減をお手伝いしました。こうした取り組みを通して、同社を日本初の二酸化炭素ゼロの製麺企業へと導いたことがご縁となり、同社のリブランディングや商品開発をお手伝いすることになりました。

同社の代表商品である「神の白糸」というネーミングの由来を調べていくと、井上製麺の工場は近隣の仁比山神社のかつての境内地にあり、これまで長きにわたって氏子総代として神社を護ってきた歴史に加えて、「神の白糸」という名前も神社からいただいたものであることがわかりました。

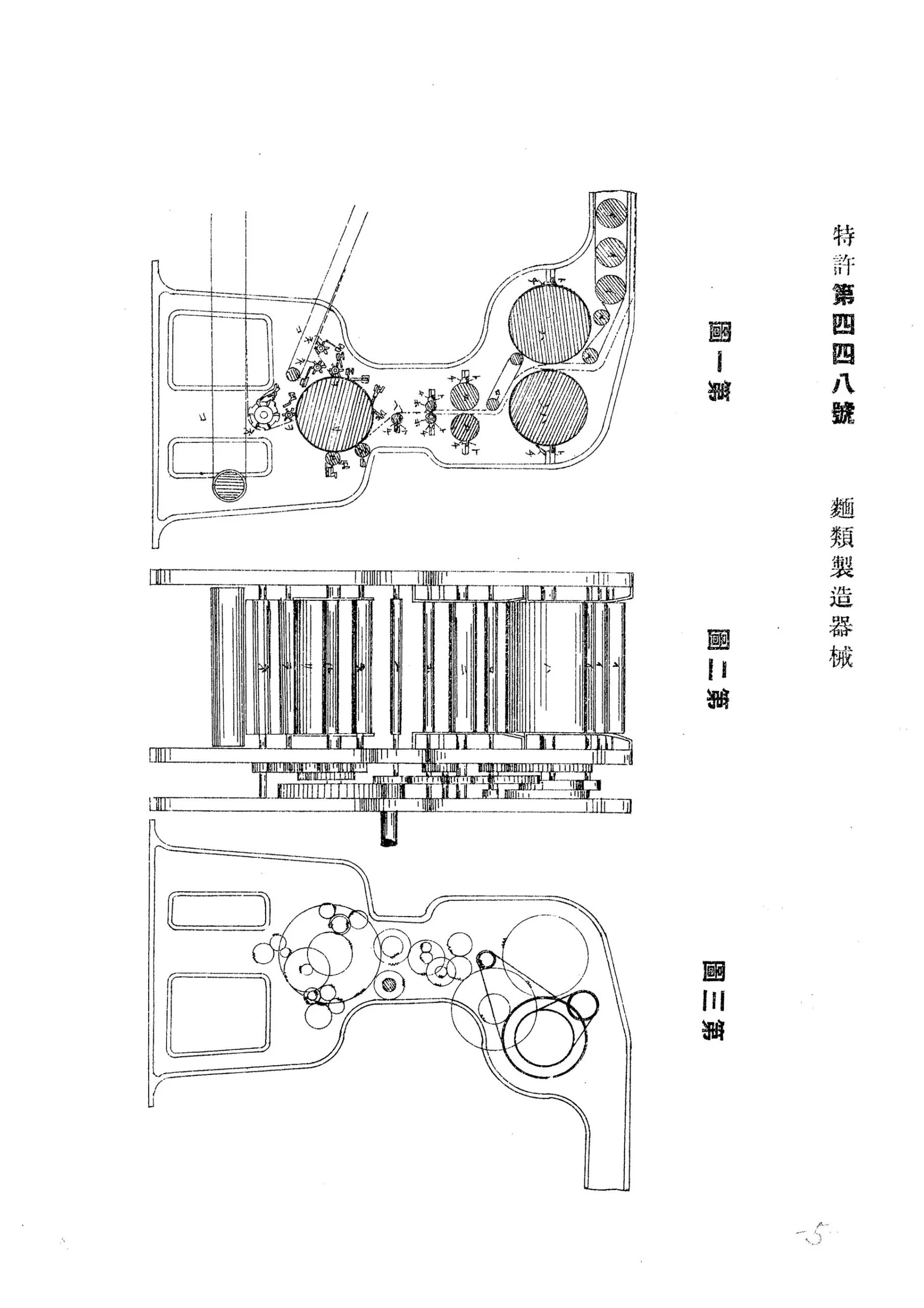

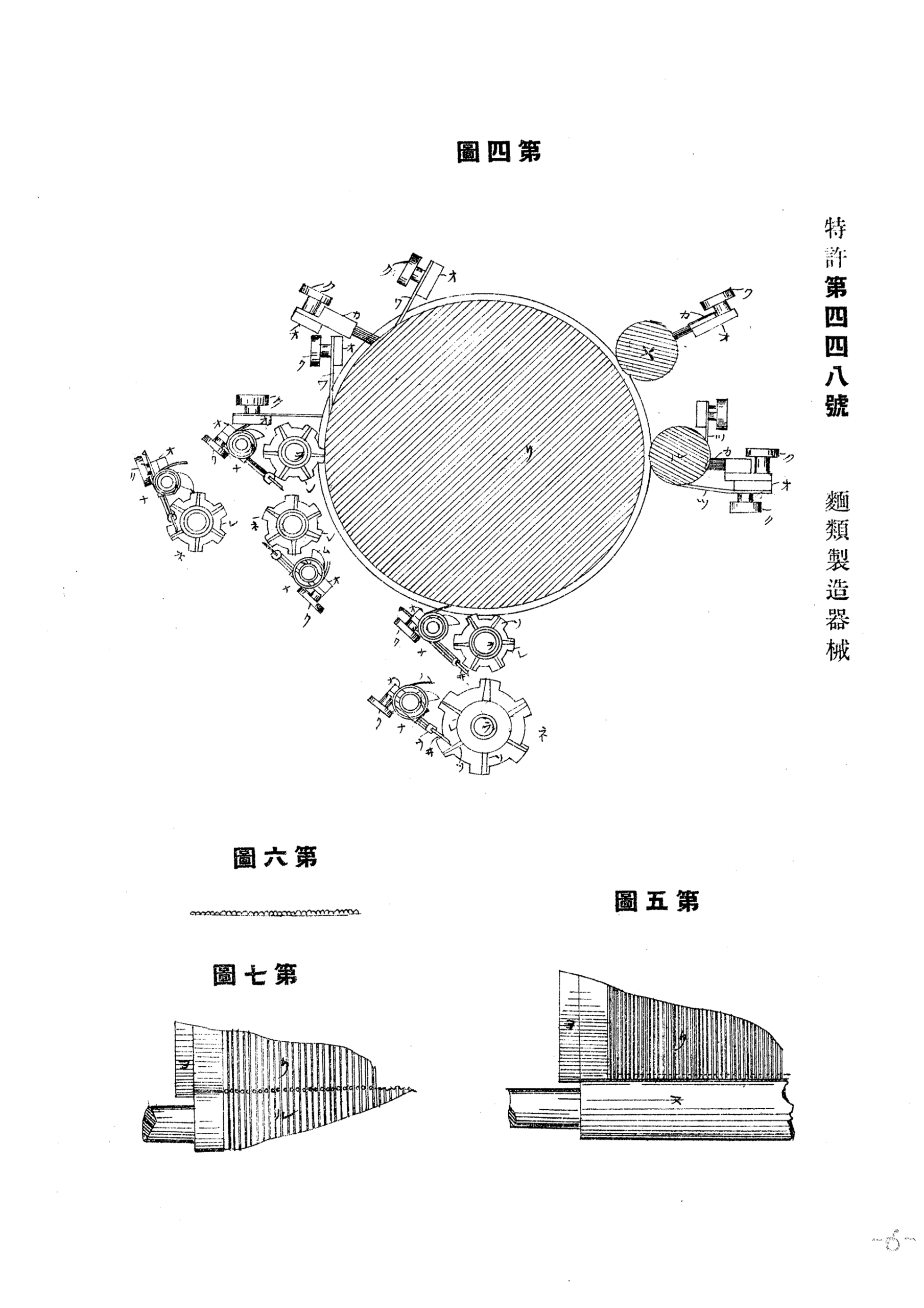

さらに驚くことに、井上製麺は世界中のパスタなどを含む、機械式製麺の元祖という歴史を持つ企業であることがわかりました。世界初の機械式製麺機は佐賀で発明され、井上製麺はそれを最初に導入した企業の一つだったのです。

こうした神社との御縁と唯一無二のストーリーをリブランディングの中心に据え、私たちは「神そうめん」「神ひやむぎ」「神うどん」「神ラーメン」など「神シリーズ」として展開するブランド戦略を提案しました。

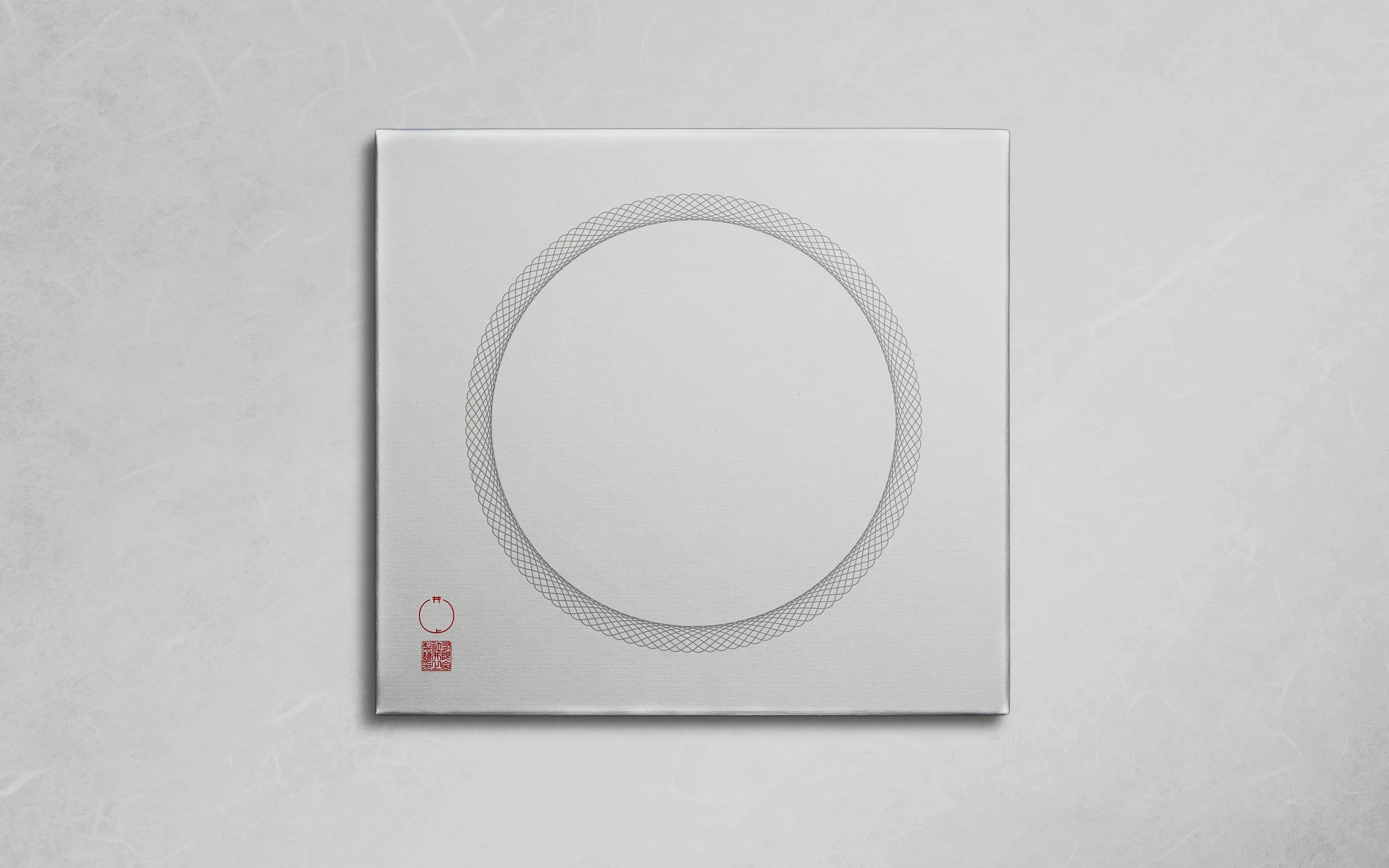

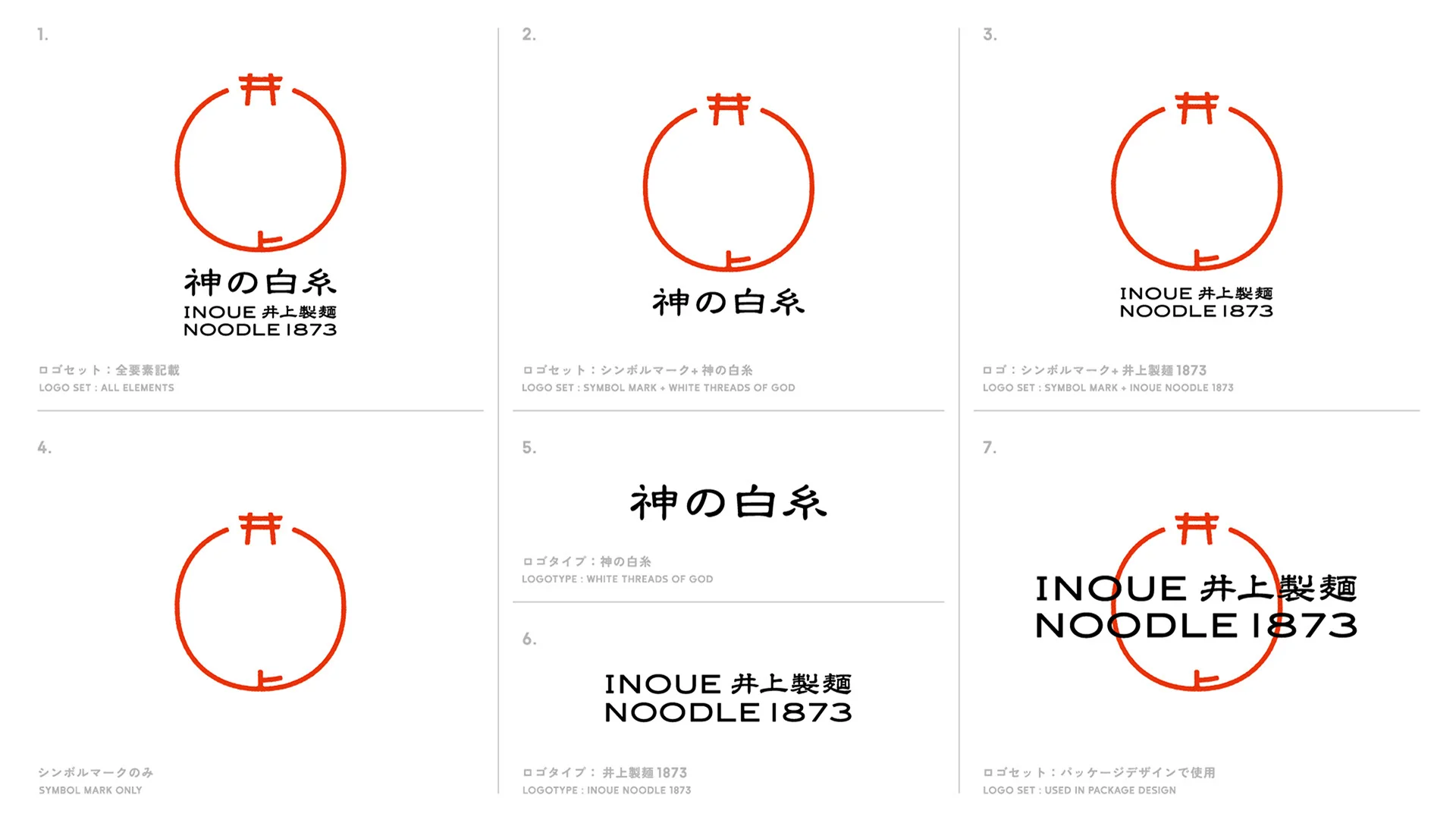

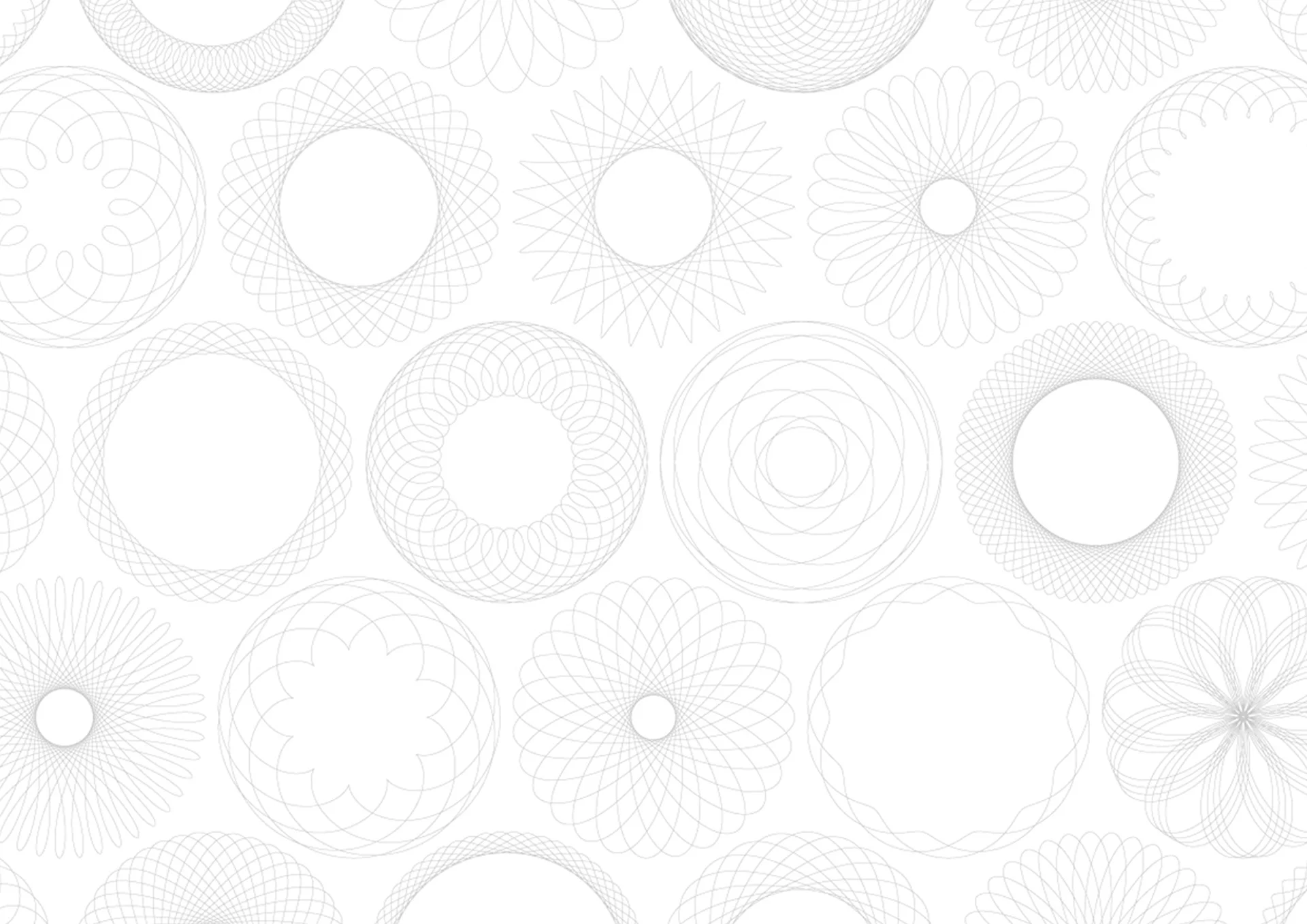

機械式製麺の元祖を示すブランドアイデンティティとして、歯車型の定規「スピログラフ」による幾何学模様を設計し、「機械によって神のような美しさが生まれる」デザインを体現。神社の御札に着想を得てデザインしたすべての商品パッケージにスピログラフ柄を大きく展開しています。同時に刷新した井上製麺の企業ロゴは、「井」の文字を神社の鳥居に見立て、神から賜ったものであることを示す「上」と合わせたデザインになっています。

新商品「神ラーメン」シリーズではスープの共同開発にも携わり、化学調味料や動物性原料を一切使用しないビーガン仕様のスープが生まれました。日本初の脱炭素化を実現した、地球にも地域にも優しい製麺企業としてのストーリーを、世界に伝えることを目指しています。

WILL

自然と文化を支える

地場産業へ。

井上製麺では、毎年7月7日のそうめんの日に「神の白糸」を仁比山神社に奉納しています。売上の一部は神社に寄進され、また地元の山を守る活動によって全製品がカーボン・オフセットされています。地域の神社や自然とともに麺づくりを行う井上製麺のブランディングのように、持続可能な地域ブランドによって地域の文化が永く続いていくことが私たちの願いです。

機械式製麺機の導入や全商品の脱炭素化など、「世界初」「日本初」を実現してきた佐賀県の小さな製麺企業のトランスフォーメーションの先に私たちが見据えるのは、地球や地域にとって優しい地場産業のあり方をこれからのスタンダードにしていくことです。地域の産業が発展するほど、森が回復する、体に優しく美味しいものが食べられる、再生可能なエネルギーが循環する、防災が徹底された安心・安全な地域になるー。こうした地域の未来を実現していくために、これからも私たちは自然と文化を支える地場産業に寄与する取り組みを続けていきます。

INFORMATION

- What

- INOUE NOODLE

- When

- 2024

- Where

- Saga, Japan

- Client

- Scope

- Rebranding / Logo / CI Guideline / Packaging / Exhibition / Promotion Strategy Support

- SDGs

CREDIT

- Art Direction

- NOSIGNER (Eisuke Tachikawa)

- Graphic Design

- NOSIGNER (Eisuke Tachikawa, Moe Shibata)

- Space Design

- NOSIGNER (Eisuke Tachikawa, Moe Shibata, Mahiro Kobayashi)